Here are 2 of the shapes I drew out that I liked the most, and I played with different colours for it. I chose green in the end as it is a soft, neutral colour that reflects the theme of 'green' design. I also looked at how the logo would look on textures brown paper as well as how it looks with imagery (leaves) In the end the plain designs worked well as the logo stands out well with no cluster/distractions. I also drew a diagram of how my final tin might look.

Thursday, 12 December 2013

Final Design Proposal

- It is a lightweight (low density) metal, meaning more energy is saved in transport rather than if steel were used (http://physics.stackexchange.com/questions/11727/what-makes-some-aluminium-alloys-so-strong-while-remaining-light) (http://www.matalco.com/about_aluminum.htm) - "Aluminium is among the most environmentally friendly metals on the planet".

- It's easily recycled 'Most home recycling bins, provided by your local council, usually accept metal or deposit at local recycling bank' (http://www.recycling-guide.org.uk/materials/metal.html) and 'recycling aluminium drink cans saves up to 95% of the energy needed to make aluminium from raw materials' (http://www.yorwaste.co.uk/wp-content/uploads/2012/05/Can-recycling.pdf)

- It is strong enough to protect the contents, cannot be pierced easily.

- It is suitable to give a sense of a quality and premium product, whereas in my opinion a bladder, carton or plastic bucket would not.

- More opportunities to re-use (storage for numerous things) rather than say a tetra pack.

- Easy to stir contents - In the client talk we learned that paint separates and needs to be stirred before use, it can be stirred and used straight from the bucket, doesn't require an extra container like a bladder or tetra back would.

- Less waste as you can scrape the bottom for last bits of paint, whereas a bladder or tetra pack might make it harder to get all of the paint out as you can't see inside clearly. Easily cleaned to be ready for recycling.

- Product called 'pots of paint' might look strange in something other than a container that resembles a pot.

- Square design means less space is wasted in storage/transport, and is easily stack-able.

The Label will be made from recycled card and printed on using vegetable inks, and the sleeve will be made of seed paper, allowing the user to grow plants in either their garden or within their empty paint bucket.

The back of the sleeve will feature information on how to re-use your bucket, inspired by the packaging on the Innocent Veg Pot. (Possible re-use ideas - storage, plant pot, lantern/lamp, re-fill) It will also feature information on recycling it if you do not wish to re-use, such as the nearest place to recycle it, times and dates that scrap metal men are in the area, or simply bring it back to the shop to recycle or get a re-fill.

- Some rough sleeve layout sketches and concepts.

- Some rough sleeve layout sketches and concepts.Wednesday, 4 December 2013

Transport Visuals

Transporting two paint containers together

Some rough sketches of possible ideas for transporting two containers. The first is a cardboard box, as it is cheap and recyclable, but may not be strong enough to carry two containers of paint, so it could be reinforced with a wooden frame (wooden pallet bottom, framed sides and handle) The wood would act as the strength and the card would act as protection. Could possibly add shredded paper or other insulating material to further protect the contents.

Second idea is a sort of bag for life design, something that can be re-used over and over, made from canvas fabric or woven fibers. Again this design could have added insulators such as shredded paper, or even pulped paper shapes along the bottom and sides to protect from bumps.

The third idea is to have a wooden frame with pallet bottom, that two containers fit into. Eco rope or sting would be tied over the top, allowing it to be easily picked up and moved about. This design is easily stack-able as well, but the wood might not be strong enough to hold a large amount of crates over it.

The fourth idea is a simple card design. The two containers have been wrapped up in corrugated card, fastened without glue, and held with eco string or rope.

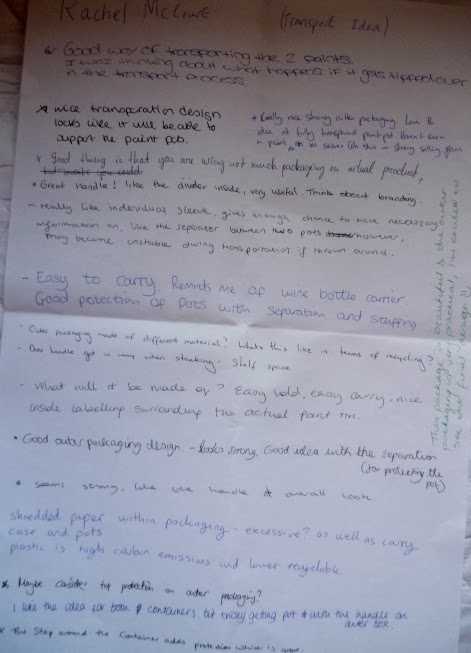

Here is the mock up version of my first idea taken by Andy in class, as well as the sheet of comments about it from my peers -

Some rough sketches of possible ideas for transporting two containers. The first is a cardboard box, as it is cheap and recyclable, but may not be strong enough to carry two containers of paint, so it could be reinforced with a wooden frame (wooden pallet bottom, framed sides and handle) The wood would act as the strength and the card would act as protection. Could possibly add shredded paper or other insulating material to further protect the contents.

Second idea is a sort of bag for life design, something that can be re-used over and over, made from canvas fabric or woven fibers. Again this design could have added insulators such as shredded paper, or even pulped paper shapes along the bottom and sides to protect from bumps.

The third idea is to have a wooden frame with pallet bottom, that two containers fit into. Eco rope or sting would be tied over the top, allowing it to be easily picked up and moved about. This design is easily stack-able as well, but the wood might not be strong enough to hold a large amount of crates over it.

The fourth idea is a simple card design. The two containers have been wrapped up in corrugated card, fastened without glue, and held with eco string or rope.

Here is the mock up version of my first idea taken by Andy in class, as well as the sheet of comments about it from my peers -

Tuesday, 3 December 2013

Materials Research

Plastic -

"Bioplastics are plastics derived from renewable biomass sources, such as vegetable fats and oils, corn starch, pea starch or microbiota. Common plastics, such as fossil-fuel plastics, are derived from petroleum- these plastics rely more on fossil fuels and produce more greenhouse gas. Some, but not all, bioplastics are designed to biodegrade. Biodegradable bioplastics can break down in either anaerobic or aerobic environments, depending on how they are manufactured. There is a variety of materials that bioplastics can be composed of, including: starches, cellulose, or other biopolymers. Some common applications of bioplastics are packaging materials, dining utensils, food packaging, and insulation." http://en.wikipedia.org/wiki/Bioplastic

'rPET (recycled polyethylene terephthalate) is the most common plastic that is being recycled back into primary applications (i.e. bottles recycled back into bottles and not ‘down-cycled’ into lesser products like park furniture). Recycled plastics reduce the amount of fossil fuel resources, have a lower carbon footprint than virgin plastics, divert material from landfill and can themselves be recycled. ' (http://www.londonbiopackaging.com/about-our-products/our-materials/)

If I choose to use plastic in my design I will make sure to look into using 'rPET' and 'bioplastics' as they are the greener option than common plastics. Also, I would consider the ideas and methods used in the Coca-Cola 'PlantBottle Packaging' which uses plant based PET plastic as well as recycled PET Plastic.

http://www.coca-cola.co.uk/environment/plantbottle/eco-friendly-plastic.html

Metal -

Aluminium - 'Is among the most environmentally friendly metals on the planet. On a percentage basis it is the most recycled of any industrial metal. Aluminum is an extraordinarily versatile material. The range of forms it can take (castings, extrusions and tubes, sheet & plate, foil, powder, forgings, etc.) and variety of surface finishes available (coatings, anodizing, polishing, etc.) means it lends itself to a wide range of products, many of which we use every day of our lives. As well as its versatile form, the metal’s light weight (a third of steel) and numerous material qualities – represented by a wide range of alloys – mean that products have been designed for use in all areas of modern life.' (http://www.matalco.com/about_aluminum.htm)

'Recycling aluminum cans saves precious natural resources, energy, time and money. Aluminum cans are unique: Within 60 days, a can is recycled, turned into a new can and back on store shelves. Aluminum is a sustainable metal and can be recycled over and over again. In 2007, 54 billion cans were recycled, saving the energy equivalent of 15 million barrels of crude oil.' (http://earth911.com/recycling/benefits-of-aluminum-can-recycling/)

'Aluminium doesn't occur naturally in the earth’s crust, it has to be extracted from its ore – bauxite – which is mined and then smelted in a very energy-intensive process. Recycling aluminium reduces the need to mine bauxite, which, as we have seen, can have negative consequences for the surrounding areas and the people living there. Compared to mining and smelting, recycling aluminium drink cans is far less energy intensive. Recycling aluminium requires only 5% of the energy and produces only 5% of the CO2 emissions as compared with primary production.

A recycled aluminium can saves enough energy to run a television for three hours. Aluminium can be recycled indefinitely, as reprocessing does not damage its structure. Aluminium is also the most cost-effective material to recycle. It is one of the easiest materials to recycle. New drinks cans appear on the shelf just six weeks after recycling!'(http://myzerowaste.com/articles/food/why-recycle-tins-and-cans/)

Cartons/ Tetra Pak -

http://www.tetrapak.com/uk

Possibility, though not as strong as plastic or metal would be, possibly resulting in more spillage issues. Also harder to recycle, as many different materials are layered into its design (paperboard, aluminium, polyethylene) However, there are more eco-friendly designs being designed such as 'Eco Carton' -

http://www.indiegogo.com/projects/unique-eco-carton-an-authentic-alternative-to-plastic-bottles-heal-our-planet

The paper water bottle

- something I have never come across before, but seems like an interesting idea -

http://bestinpackaging.com/2009/01/06/the-paper-water-bottle/

Recycled Paper

'Recycled paper products contribute to the diversion of material from landfill and results in less land being given over to commercial forestry which can have a negative impact on biodiversity.

Sustainable forest paper ensures that the forests from which the paper comes and managed so as not destroy the forest, to promote biodiversity and protect any indigenous peoples.' (http://www.londonbiopackaging.com/about-our-products/our-materials/)

Sugar Bagasse

"The waste material produced once sugar cane has been harvested for the sugar syrup is called bagasse. This fibrous material is a renewable resource. There is not currently adequate information on the associated carbon emissions, but as this is a waste product, it will by definition be saving carbon as it replaces what would otherwise be a requirement for some virgin material manufacture.

"Bioplastics are plastics derived from renewable biomass sources, such as vegetable fats and oils, corn starch, pea starch or microbiota. Common plastics, such as fossil-fuel plastics, are derived from petroleum- these plastics rely more on fossil fuels and produce more greenhouse gas. Some, but not all, bioplastics are designed to biodegrade. Biodegradable bioplastics can break down in either anaerobic or aerobic environments, depending on how they are manufactured. There is a variety of materials that bioplastics can be composed of, including: starches, cellulose, or other biopolymers. Some common applications of bioplastics are packaging materials, dining utensils, food packaging, and insulation." http://en.wikipedia.org/wiki/Bioplastic

'rPET (recycled polyethylene terephthalate) is the most common plastic that is being recycled back into primary applications (i.e. bottles recycled back into bottles and not ‘down-cycled’ into lesser products like park furniture). Recycled plastics reduce the amount of fossil fuel resources, have a lower carbon footprint than virgin plastics, divert material from landfill and can themselves be recycled. ' (http://www.londonbiopackaging.com/about-our-products/our-materials/)

If I choose to use plastic in my design I will make sure to look into using 'rPET' and 'bioplastics' as they are the greener option than common plastics. Also, I would consider the ideas and methods used in the Coca-Cola 'PlantBottle Packaging' which uses plant based PET plastic as well as recycled PET Plastic.

http://www.coca-cola.co.uk/environment/plantbottle/eco-friendly-plastic.html

Metal -

Aluminium - 'Is among the most environmentally friendly metals on the planet. On a percentage basis it is the most recycled of any industrial metal. Aluminum is an extraordinarily versatile material. The range of forms it can take (castings, extrusions and tubes, sheet & plate, foil, powder, forgings, etc.) and variety of surface finishes available (coatings, anodizing, polishing, etc.) means it lends itself to a wide range of products, many of which we use every day of our lives. As well as its versatile form, the metal’s light weight (a third of steel) and numerous material qualities – represented by a wide range of alloys – mean that products have been designed for use in all areas of modern life.' (http://www.matalco.com/about_aluminum.htm)

'Recycling aluminum cans saves precious natural resources, energy, time and money. Aluminum cans are unique: Within 60 days, a can is recycled, turned into a new can and back on store shelves. Aluminum is a sustainable metal and can be recycled over and over again. In 2007, 54 billion cans were recycled, saving the energy equivalent of 15 million barrels of crude oil.' (http://earth911.com/recycling/benefits-of-aluminum-can-recycling/)

'Aluminium doesn't occur naturally in the earth’s crust, it has to be extracted from its ore – bauxite – which is mined and then smelted in a very energy-intensive process. Recycling aluminium reduces the need to mine bauxite, which, as we have seen, can have negative consequences for the surrounding areas and the people living there. Compared to mining and smelting, recycling aluminium drink cans is far less energy intensive. Recycling aluminium requires only 5% of the energy and produces only 5% of the CO2 emissions as compared with primary production.

A recycled aluminium can saves enough energy to run a television for three hours. Aluminium can be recycled indefinitely, as reprocessing does not damage its structure. Aluminium is also the most cost-effective material to recycle. It is one of the easiest materials to recycle. New drinks cans appear on the shelf just six weeks after recycling!'(http://myzerowaste.com/articles/food/why-recycle-tins-and-cans/)

Cartons/ Tetra Pak -

http://www.tetrapak.com/uk

Possibility, though not as strong as plastic or metal would be, possibly resulting in more spillage issues. Also harder to recycle, as many different materials are layered into its design (paperboard, aluminium, polyethylene) However, there are more eco-friendly designs being designed such as 'Eco Carton' -

http://www.indiegogo.com/projects/unique-eco-carton-an-authentic-alternative-to-plastic-bottles-heal-our-planet

There is a problem with using Tetra Pak for paint though however, as in one of our sessions one of my peers stated that they had contacted the company about using the cartons for natural paint, and they claimed it probably isn't suitable.

The paper water bottle

- something I have never come across before, but seems like an interesting idea -

"The bottle is made from 100% renewable food safe resources, fully recyclable and can potentially be used for a number of liquid categories."This is an idea I could consider for refillable design (ie buying the main tub of paint, then buying paper water bottles of paint to refill main paint tub)

http://bestinpackaging.com/2009/01/06/the-paper-water-bottle/

Mushroom Packaging

- Another interesting idea, a material grown from mushrooms and performs like foam, is renewable, natural, home compostable and cost-competitive.

Cardboard

'Corrugated cardboard is used as one of the most fundamental items in packaging, the humble cardboard box. Used extensively throughout the world, cardboard boxes or cartons are the backbone of most transit packaging. Corrugated cardboard may at first seem like a very bad resource for use in eco-friendly packaging materials, (destruction of forests, destroying eco-systems) but this is not strictly true, as many of the paper based materials in use are cut from sustainable woodlands. Aside from this, there are other benefits to using corrugated cardboard packaging.

All cardboard boxes can be reused & recycled. This means that less resources are used in the future, as recycled corrugated cardboard can be used in making further cardboard boxes, and re-use of boxes ensures maximum life-span of the original materials. Although many corrugated cardboard boxes are not usually 100% recycled, (70-90% on average), it is possible to purchase boxes which are entirely made from recycled corrugated cardboard.

It is not just the corrugated boxes which can be made of recycled materials but also inserts for these boxes., such as those used to hold wine bottles in place or specialist die-cut inserts.' (http://www.postpack.co.uk/acatalog/Packaging_and_the_Environment.html)

All cardboard boxes can be reused & recycled. This means that less resources are used in the future, as recycled corrugated cardboard can be used in making further cardboard boxes, and re-use of boxes ensures maximum life-span of the original materials. Although many corrugated cardboard boxes are not usually 100% recycled, (70-90% on average), it is possible to purchase boxes which are entirely made from recycled corrugated cardboard.

It is not just the corrugated boxes which can be made of recycled materials but also inserts for these boxes., such as those used to hold wine bottles in place or specialist die-cut inserts.' (http://www.postpack.co.uk/acatalog/Packaging_and_the_Environment.html)

Molded Pulp

Also named moulded pulp or molded fibre, is a packaging material, typically made from recycled paperboard and/ornewsprint. It is used for protective packaging or for food service trays and beverage carriers. Other typical uses are end caps, trays, plates, bowls and clamshell containers. For many applications, molded pulp is less expensive than expanded polystyrene (EPS), vacuumed formed PET and PVC, corrugation, and foams. Molded pulp is often considered a sustainable packaging material, as defined by the Sustainable Packaging Coalition, since it is produced from recycled materials, and can be recycled again after its useful life-cycle. Molded pulp products can be made waterproof with a spray or dip coating of wax. (http://en.wikipedia.org/wiki/Molded_pulp) http://www.molded-pulp.com/

Seed Paper

'Seed paper is a type of handmade paper that includes any number of different plant seeds. The seeds themselves can still germinate after the paper making process and they can sprout when the paper is planted in soil.' (http://en.wikipedia.org/wiki/Seed_paper)

This is something I can incorporate into my design with regards to re-use, the paint pot can be used as a plant pot and the label can be planted.

Recycled Paper

'Recycled paper products contribute to the diversion of material from landfill and results in less land being given over to commercial forestry which can have a negative impact on biodiversity.

Sustainable forest paper ensures that the forests from which the paper comes and managed so as not destroy the forest, to promote biodiversity and protect any indigenous peoples.' (http://www.londonbiopackaging.com/about-our-products/our-materials/)

Sugar Bagasse

"The waste material produced once sugar cane has been harvested for the sugar syrup is called bagasse. This fibrous material is a renewable resource. There is not currently adequate information on the associated carbon emissions, but as this is a waste product, it will by definition be saving carbon as it replaces what would otherwise be a requirement for some virgin material manufacture.

Sugar bagasse is turned into packaging products from its raw form using a process of heating, pulping and then pressurised moulding. These are heat resistant and microwaveable making them ideal as hot food containers and best of all, naturally compostable." (http://www.londonbiopackaging.com/about-our-products/our-materials/)

Vegetable Ink

Conventional printing inks are petroleum-based and used with alcohol-based solvents which, as they evaporate, emit Volatile Organic Compounds (VOCs) into the atmosphere. VOCs cause environmental pollution and are a health hazard to pressroom workers as well as creating ozone pollution. Petroleum-based inks emit between 25% and 40% VOCs as they dry, whereas vegetable-based ink emissions rates can be as low as 4%.

Petroleum-based inks contain products refined from crude oil and the energy required for extraction, refining and treatment for this is high which adds to the environmental damage. Crude oil is also a fossil fuel , resources of which are dwindling very fast. Vegetable oil based inks, on the other hand, are derived from renewable resources.

Vegetable based inks also have the added benefit of being easier to remove from recycled paper and print during the de-inking process of recycling. (http://www.hhreedsprinters.co.uk/vegetable-based/)

Petroleum-based inks contain products refined from crude oil and the energy required for extraction, refining and treatment for this is high which adds to the environmental damage. Crude oil is also a fossil fuel , resources of which are dwindling very fast. Vegetable oil based inks, on the other hand, are derived from renewable resources.

Vegetable based inks also have the added benefit of being easier to remove from recycled paper and print during the de-inking process of recycling. (http://www.hhreedsprinters.co.uk/vegetable-based/)

Subscribe to:

Comments (Atom)